Kamoer High Flow Peristaltic Pump WiFi AC100-240V UIP E Stepper Dosing Pump with RS485,Foot Switch for Lab and Filling 7.9x11.1

SPECIFICATIONS

Application: Transfer

Brand Name: kamoer

Certification: CE

Control mode: Touch screen, foot switch, 0-5/10V analog quantity, RS485 communication

Fuel: Electric

High-concerned chemical: None

Humidity: 0~80℃

Lifetime: More than 6000 H

Model Number: UIP-E

Number of rotors: 3 rotors

Origin: Mainland China

Overall weight: 3.15KG

Peristaltic Pump Flow Rate: 0.5~1500ml/min

Peristaltic Pump Motor: Stepper Motor

Peristaltic Pump Voltage: AC 100-240 V

Power (W): Electric

Power Source: Electric

Pressure: Low Pressure

Pump Head: Single Head-KK1800

Size: 324*164*219mm(L*W*H)

Standard or Nonstandard: Standard

Structure: Roller pump

Temperature: 0~60℃

Theory: Peristaltic pump

Use: Water

Kamoer 0.5-1500ml/min UIP-E Affordable High Flow

Peristaltic Pump AC100-240V Bluetooth Compatible Filling Pump with APP Remote Control

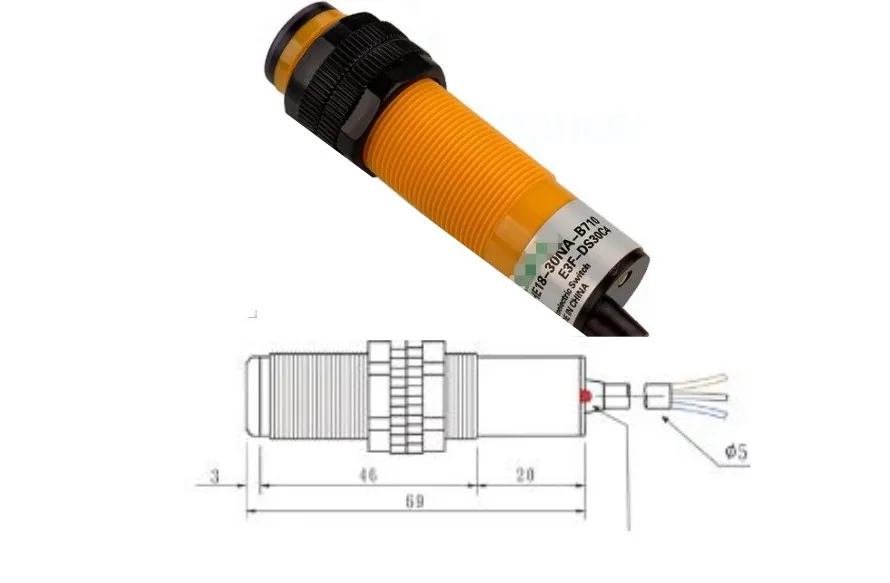

· Added photoelectric sensor

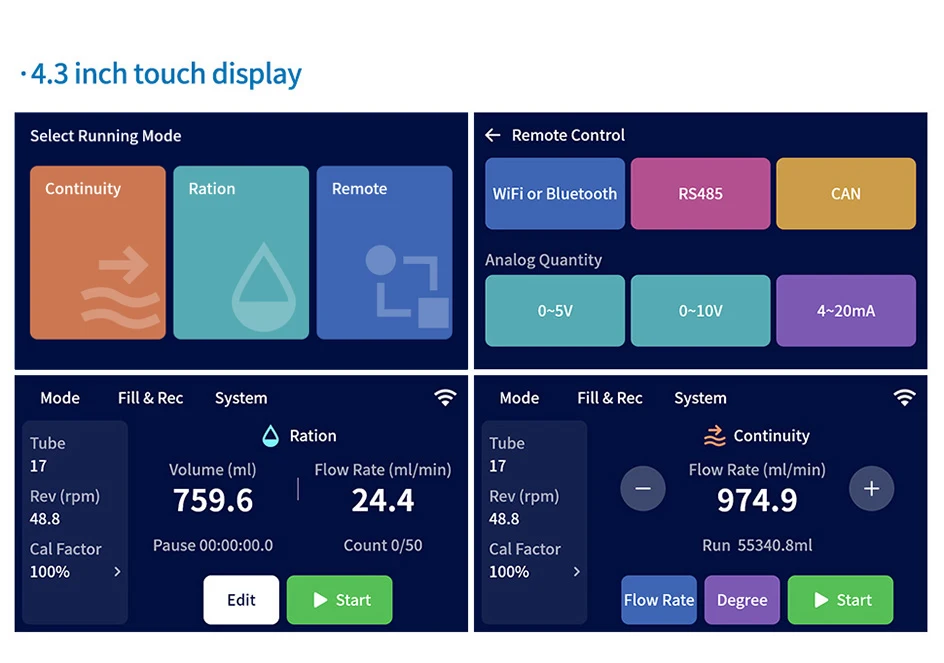

· Includes a 4.3 inch touch screen for easy operation.

· Rich control methods, including touch screen, foot switch, RS485 and voltage analog operation.

· Supports flow rate calibration.

· Supports continuous mode and quantitative mode operation.

· Supports power-down parameter saving.

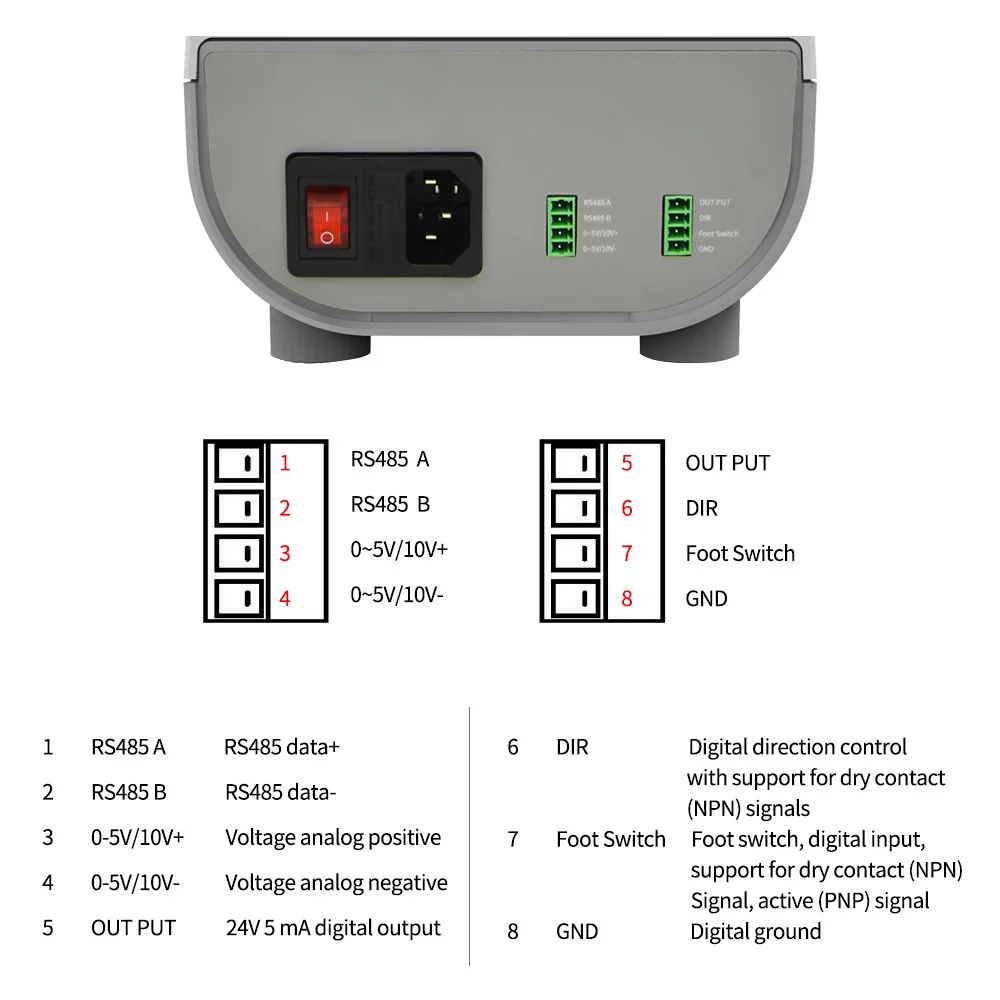

· Back interface adopts quick-connect terminals, easy to connect.

· Support remote firmware upgrade.

Basic parameters

Basic Parameters |

UIP WIFI E with Stepper motor |

Power supply |

AC100-240V |

Flow ml/min |

0.5-1500ml/min |

Power(Max) |

<50W |

Weight |

About 3.15KG |

Noise |

≤65dB(Less than 60dB measured at a distance of 50cm) |

Speed range |

0.1-350 rpm |

Speed adjustment resolution |

0.1 rpm |

Display mode |

LED 4-digit digital tube |

Control method |

Touch screen, foot switch, external analog (0-5V, 0-10V), 485 communication control |

Working mode |

Continuous Mode, Quantitative Mode and Remote Mode |

18# Silicone-200H |

1589ml/min |

18# BPT-1000H |

1428ml/min |

Working mode description

1.Continuous mode:

Applied to non-fixed amount of added occasions, the pump running and stopping the user through the touch screen or foot switch to trigger; in the title bar, select "switch mode" to enter the mode selection interface, click on "continuous" to enter the continuous mode working interface, click on the start, the pump will run continuously until the stop button is clicked. After clicking start, the pump will run continuously until the stop button is clicked;\

2. Ration Mode:

Suitable for filling occasions, the pump runs for a dosage, and then stops automatically, the user can manually trigger the start, you can also set the number of cycles, so that the pump runs cyclically; Select "Switch Mode" in the title bar to enter the mode selection interface, click "Ration" to enter the dispensing mode working interface;In the ration mode, there are two working modes, namely, semi-automatic working mode and full-automatic working mode;

Semi-automatic working mode:

after volume setting, click the start button to start running, the volume (flow) displayed on the screen starts counting down, when the count value changes from the set value to 0, the pump stops working, click start again, the pump runs again in the above way;

Full-automatic working mode:

set the number of times of operation, volume, pause time, click to start running, the volume displayed in the screen (flow) began to count down, when the count value from the set value to 0, the pump stops working, at the same time the middle of the screen began to count down the pause time, when counting down to 0, the pump automatically restarted the work of the pump for each run, the number of times h plus 1, when the pump cycle through the set number of times of operation, the pump stops running, waiting for a second time, waiting for a second time, the pump runs again in the above way. When the pump cycles through the set number of times, the pump stops running and waits for clicking start to begin the next cycle;(Note: Before the pump starts to run, the pump tube must first be filled with liquid and drained of air to ensure the accuracy of the pump;)

3.Remote mode:

In remote mode, users can control the operating status of the pump through non-touch screen methods, such as RS485, 0~5V/10V analog, suitable for supporting user systems; select "Switch Mode" in the title bar to enter the mode selection interface, and click "Remote" to enter the remote control interface;

4. Analog control:

In the application scenario that requires the use of analog control devices, you can choose analog control to achieve motor speed control, the value of the analog determines the running speed of the motor; analog has two ways: current or voltage, of which the current mode can be customized according to the demand; according to the definition of analog interface to connect the analog communication line (the following figure), select the corresponding analog in the remote control interface, click to enter the corresponding analog control interface.

Each interface definition

1 RS485 A RS485 data+

2 RS485 B RS485 data-

3 0-5V/10V+ Voltage analog quantity positive

4 0-5V/10V- Voltage analog quantity negative

5 OUT PUT 24V 5 mA digital output

6 DIR: Digital directional control, supporting dry

contact (NPN) signal

7 Foot Switch: Foot switch, digital input, supporting dry

contact (NPN) signal, active (PNP) signal

8 GND Digitally

Multiple Applications

# Food industry

# Factory production

# Laboratory, research institute

# Research institutions

# Filling and dispensing

# Medical equipment

Packing List

1× UIP WIFI E;

1× Power cable;

1× Foot switch;

1× Tube(2m silicone)

Other Accessories

Photoelectric sensor switch: Photoelectric sensor used to identify the presence or absence of solution bottles for automatic filling Sensor recognition distance length 0.5 meters

Contact us if any question.