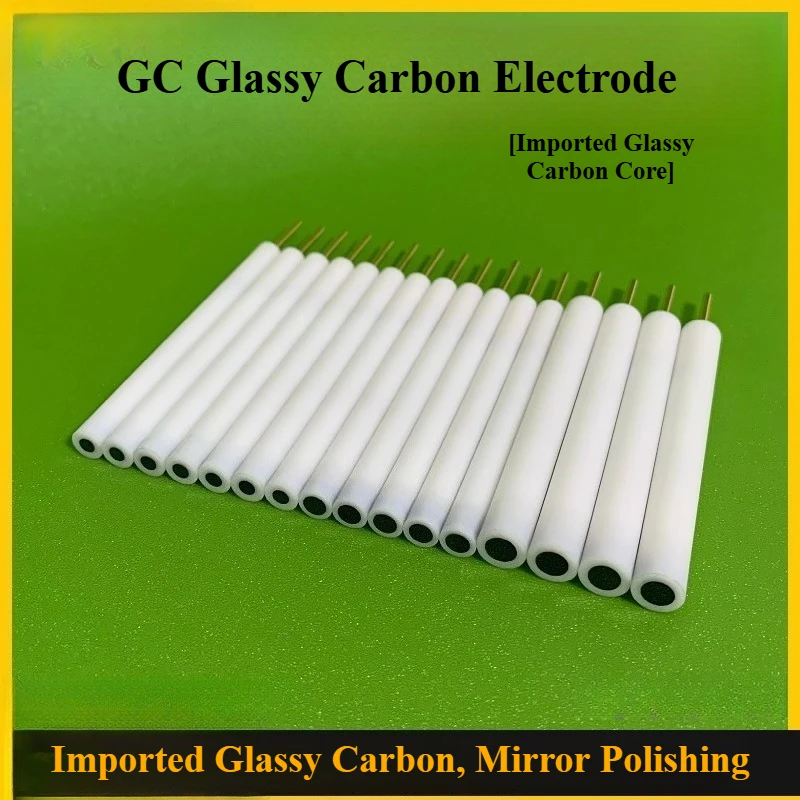

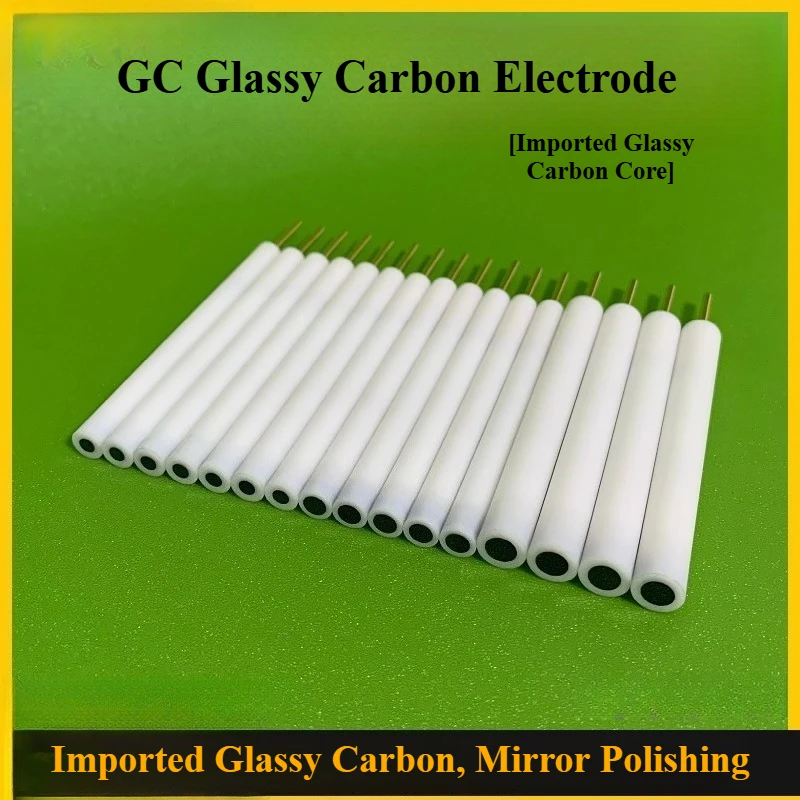

Product Name: Glassy Carbon Electrode (Gc)

Product Features: Imported glassy carbon, mirror-polished electrode, customizable (the conventional length of PTFE is 70mm, which can be customized), no need for potential calibration.

Product Sizes:

- Glassy carbon core diameter: 1mm; PTFE outer diameter: 6mm; copper column length: 15mm, diameter: 2mm

- Glassy carbon core diameter: 2mm; PTFE outer diameter: 6mm; copper column length: 15mm, diameter: 2mm

- Glassy carbon core diameter: 3mm; PTFE outer diameter: 6mm; copper column length: 15mm, diameter: 2mm

- Glassy carbon core diameter: 4mm; PTFE outer diameter: 6mm; copper column length: 15mm, diameter: 2mm

- Glassy carbon core diameter: 5mm; PTFE outer diameter: 8mm; copper column length: 15mm, diameter: 2mm

- Glassy carbon core diameter: 6mm; PTFE outer diameter: 10mm; copper column length: 15mm, diameter: 2mm

Glassy Carbon Electrode (GCE)

Glassy carbon, abbreviated as "bo tan" in Chinese, is an amorphous carbon with a glass-like appearance. It is produced by slowly heating materials such as polyacrylonitrile resin or phenolic resin to a high temperature (up to 1800℃) in an inert atmosphere. It is a suitable electronic conductor material for making electrodes and is also widely used in table tennis bat blades.

The glassy carbon electrode is the abbreviation of the glass carbon electrode.

The advantages of the glassy carbon electrode include good electrical conductivity, high chemical stability, small thermal expansion coefficient, high hardness, good airtightness, and a wide potential application range (approximately from -1 to 1V relative to the saturated calomel electrode). It can be fabricated into electrode shapes such as cylinders and discs. Using it as a substrate, mercury film glassy carbon electrodes and chemically modified electrodes can also be produced. It is increasingly widely applied in electrochemical experiments or electroanalytical chemistry.

Electrode Characteristics:

The glassy carbon electrode is one of the widely used working electrodes. It is an excellent inert electrode with properties such as good electrical conductivity, high hardness, high finish, high hydrogen overpotential, a wide polarization range, and chemical stability. It can be directly used as an inert electrode for anodic stripping, voltammetric determination of cathodes and variable valence ions, and can also serve as a chemically modified electrode.

Electrode Treatment and Maintenance: (Note: Try to avoid ultrasonic cleaning. It is recommended to use polishing powder and a polishing plate to clean residual substances on the electrode)

It is essential to ensure that the surface of the glassy carbon is mirror-like and clean. Since the surface of glassy carbon is easily contaminated by some organic metal compounds, which severely affects measurements (such as no peaks, miscellaneous peaks, or poor reproducibility), cleaning treatment must be performed before measurement. There are three main methods:

Chemical Method:

- Soak and scrub with 3 mol nitric acid.

- Soak and scrub with a 1:1 mixture of ammonia water and absolute ethanol or ethyl acetate.

- It can also be scrubbed with alcohol and then soaked in 6M HCl or 4M HNO₃.

Electrochemical Treatment: That is, repeatedly polarize (reset-scan) within the voltage range of +0.8V to -1.8V (under the condition of 0.5M KCl, pH 7, and oxygen removal), from anode to cathode to cathode.

For severe contamination, pitting, or scratches, mechanical treatment can be conducted. First, use 5000-mesh sandpaper to polish in an "8"-shaped pattern until the electrode surface is smooth without scratches or foreign matters. Then, use 0.05μm polishing powder on deerskin or polishing flannelette for dry friction polishing, and then wipe the surface of the electrode tip clean with a clean polishing cloth. Several methods can also be combined according to the condition of the electrode. It is not advisable to soak the electrode in strong acids, strong alkalis, or organic solvents for a long time.

Since the glassy carbon electrode is an inert electrode, when using plating scanning materials, it becomes a scanning electrode. For example, plating mercury, copper, or gold can make it a mercury film, copper film, or gold film electrode. For instance, in anodic stripping, mercury plating, and gold plating:

There are two methods for mercury plating on glassy carbon:

-

The first is simultaneous mercury plating. That is, add a certain amount of Hg⁺ (generally using mercuric oxide and mercuric nitrate) to the sample to be analyzed. Under the potential for electrolytic enrichment of the ions to be measured, an amalgam is formed simultaneously. After scanning and stripping, at a more positive potential, the ions to be measured or the mercury film are completely stripped. The electrode can also be taken out and the mercury film wiped clean with filter paper. This ensures that the electrode surface remains in its original state during the second analysis to guarantee reproducibility. Generally, the concentration of mercury ions is 500-1000 times that of the measured ions.

-

The second is pre-plated mercury film:

- Electrodeposit mercury for a long time at a potential more positive than the electrolytic potential of the ions to be measured. For example, when measuring copper, a mercury film can be prepared by long-term electrodeposition at -0.2V to prevent the risk of electrodepositing copper, lead, cadmium, and zinc. This method has low efficiency and takes a long time.

- Under the condition of simultaneous mercury plating, after electrodeposition for a period of time, scan and strip, and then strip for a certain time at the termination potential to strip the ions to be measured. Repeat the enrichment-stripping process several times to obtain a mercury film without the ions to be measured.

For example, in 0.5M KCl + 2×10⁻²M Hg⁺ with a few drops of saturated Na₂SO₃, enrich by stirring at -1.4V for 5-10 minutes. Under stirring, scan to -0.1V within 15 seconds, continue to stir and strip at -0.1V for 30 seconds, then stir and enrich again in the reset state for 5-10 minutes, stir and scan to -0.1V within 15 seconds, and then stir and strip at -0.1V for 30 seconds. After the solution is static, take out the electrode and rinse the electrode rod with water to prevent the coating from breaking. When plating mercury, it should be noted that there should be no bubbles adhering to the bottom of the electrode; otherwise, the mercury coating will be uneven or fail to plate. If not used for a short time, the electrode can be soaked in 1:1 nitric acid. When in use, wash it and then plate. If not used for a long time, remove the mercury, clean it, and store it dry. The basic essentials of gold plating on glassy carbon are the same as those of mercury plating.

Grinding Glassy Carbon Electrodes:

Use nylon cloth for wet grinding, and deerskin or polishing flannelette for dry grinding.

It is generally recommended to use dry grinding: deerskin + 0.05μm polishing powder, as this achieves a better grinding effect.

Recommended notes: Try to avoid ultrasonic cleaning of glassy carbon electrodes. If there is incorrect data, the electrode can be repaired by polishing and grinding.

Glassy Carbon Electrode: For glassy carbon electrodes, the peak potential difference when measuring potassium ferricyanide is within the normal range if it is less than 100mV; if it exceeds 100mV, simply re-grind the electrode.

We can customize electrodes of different sizes.

Product Description:

- Use 0.3-0.5μm polishing powder; for a mirror effect, use 0.05μm polishing powder. Polish the electrode in a figure-eight pattern.

- For customized glassy carbon electrodes, it is recommended that the PTFE wall should not be too thin, as this will affect the service life of the electrode.